Chassis and Suspension

Divide and conquer

The MGA has a separate chassis and bodyshell, unlike all the modern cars you can see in the regular traffic jams. While working on the bodyshell we kept the bodyshell attached to the chassis for the latter to provide the necessary support. Now with most of the rust damage on the body repaired and replaced with new sheet metal, it is time to remove the shell from the chassis. We asked a couple of strong neighbours to assist and lift the bodyshell from the chassis and placed it on a wooden frame so it can be moved around without too much effort. After that the bodyshell is transported to an expert to blast off the paint using glass beads and coat it with an epoxy primer.

The MGA has a separate chassis and bodyshell, unlike all the modern cars you can see in the regular traffic jams. While working on the bodyshell we kept the bodyshell attached to the chassis for the latter to provide the necessary support. Now with most of the rust damage on the body repaired and replaced with new sheet metal, it is time to remove the shell from the chassis. We asked a couple of strong neighbours to assist and lift the bodyshell from the chassis and placed it on a wooden frame so it can be moved around without too much effort. After that the bodyshell is transported to an expert to blast off the paint using glass beads and coat it with an epoxy primer.

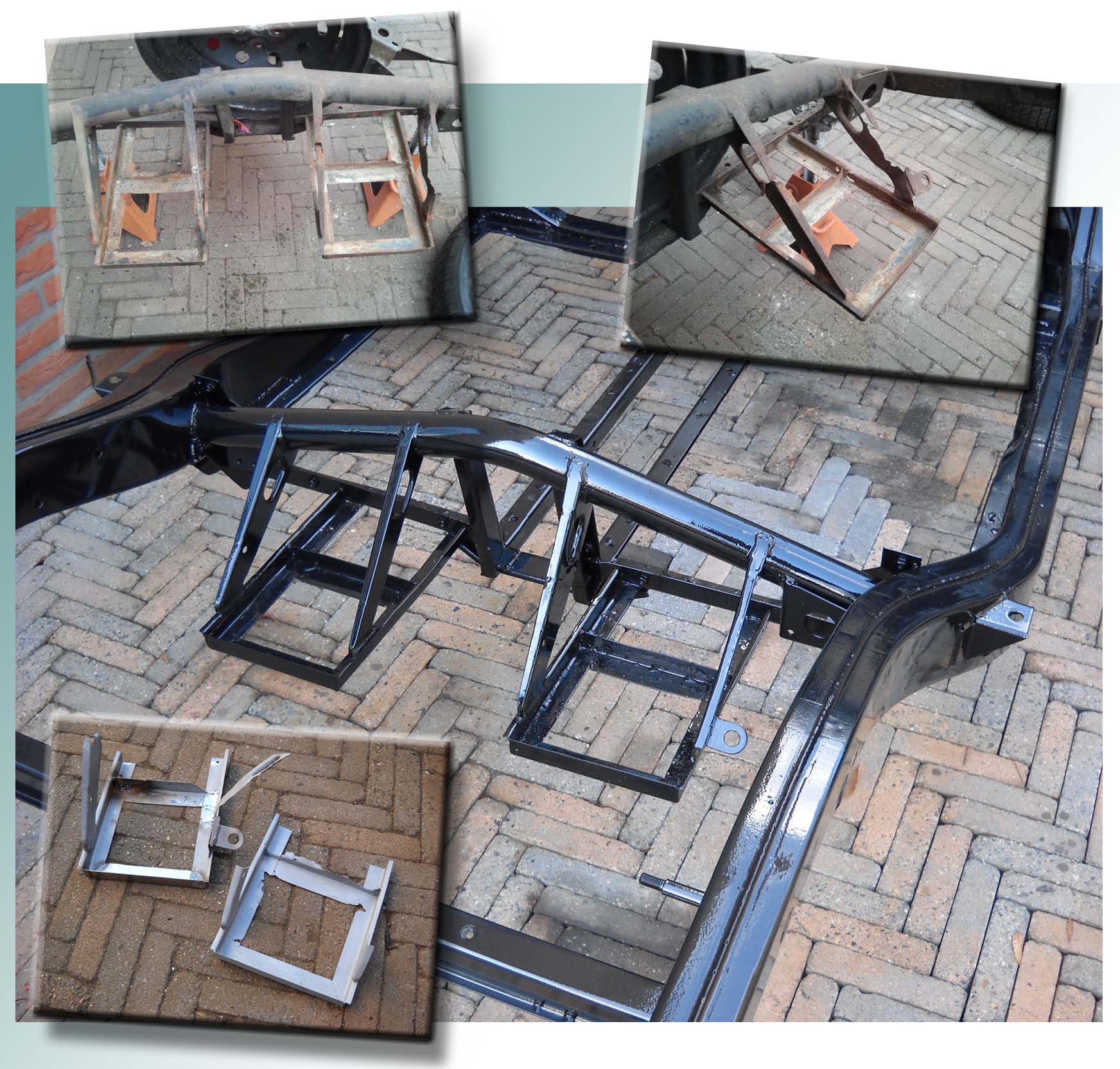

With the bodyshell removed working on the chassis becomes much easier. I cut out some dented parts in the frame to hammer it straight on the bench and weld it back in. Compared with the thin sheet metal of the bodyshell these chassis parts weld much easier. The battery tray was badly rusted. After glass bead blasting the bad parts were cut out and replicated in new sheet metal.

With the bodyshell removed working on the chassis becomes much easier. I cut out some dented parts in the frame to hammer it straight on the bench and weld it back in. Compared with the thin sheet metal of the bodyshell these chassis parts weld much easier. The battery tray was badly rusted. After glass bead blasting the bad parts were cut out and replicated in new sheet metal.

The chassis was in a much better shape as compared with the bodyshell. That is understandable given the much thicker sheet metal used in the chassis. A local paint shop blasted and painted the chassis with the fresh layer of shiny black paint. Once back we could not wait to put the first parts of the rear axle back on the chassis. Cannot wait to start the re-assembly. During cold days we collected all the bolts and nuts for a particular part to make assembly easier and faster. Just like putting together a new car with these clear and newly galvanized bolts and nuts.

Fixing the rear axle

On a nice day in March Daan and I removed the rear suspension from the car. The gaskets has been leaking a bit and the oil that used to be in the differential housing now settled on the outside of it. Over the years is was able to different types of dust and sand from the California roads. The 30 years in storage turned this mixture into a material that will probably be very suitable to use for an average highways top layer. It took some persuasion to chip it off. The differential itself looks ok. Just new oil seals and gaskets, and of course a new layer of paint.

On a nice day in March Daan and I removed the rear suspension from the car. The gaskets has been leaking a bit and the oil that used to be in the differential housing now settled on the outside of it. Over the years is was able to different types of dust and sand from the California roads. The 30 years in storage turned this mixture into a material that will probably be very suitable to use for an average highways top layer. It took some persuasion to chip it off. The differential itself looks ok. Just new oil seals and gaskets, and of course a new layer of paint.

We also had a first batch of parts sandblasted: Brake drums, bumper mounts, suspension arms, the metal frame of the dashboard, the fuel tank and the housing of the heater core housing. We put a rust preventive topcoat on top, and so all these parts look like new again. At the same time, all the rusty bolts and nuts have been re galvanized, while parts that were beyond repair are replaced. All bearings will be replaced any ways. Almost all of them made some sounds when turned by hand. Once mounted it is amazing how much noise old bearings van produce: just replace all of them.

We also had a first batch of parts sandblasted: Brake drums, bumper mounts, suspension arms, the metal frame of the dashboard, the fuel tank and the housing of the heater core housing. We put a rust preventive topcoat on top, and so all these parts look like new again. At the same time, all the rusty bolts and nuts have been re galvanized, while parts that were beyond repair are replaced. All bearings will be replaced any ways. Almost all of them made some sounds when turned by hand. Once mounted it is amazing how much noise old bearings van produce: just replace all of them.

Before and after